DEFENSE

The United States Military demands the most precise metal fabrication and welded parts that are aligned to support Government requirements.

Our Promise

At Aarons Fabrication, we never take our role in serving the men and women in the armed forces for granted. We’re committed to producing products of exceptional quality that withstand the most challenging demands of the defense industry. Having such a diverse background of working with the Armed Forces’ research and development facility for advanced technology in ground systems, all the way to world-class Defense suppliers, we are sure of it we will meet your strict requirements, tight deadlines, and quality standards.

OUR SERVICES

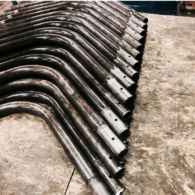

Tube Fabrications- Aaron’s offers tube fabrication services to compliment our tube bending capabilities. Our experienced team allows us to provide a variety of welding, light machining, and turning services. Some of the material types we work with include stainless, and aluminum. We have completed many tube fabrication projects directly for one of the leading Military Ground Vehicle R&D centers in the nation, including swaged, bent, and machined tube assemblies for military ground vehicles.

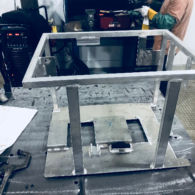

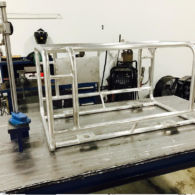

Weldments- Welding is a core part of our manufacturing process at Aaron’s Fabrication. Our certified welders are held to the highest quality standards within the industry. We offer both GMAW and GTAW processes. We specialize in welding the following set of materials: Aluminum, Stainless, Steel, and Armor (Steel). Our company is a direct Government supplier of welded assemblies. Aaron’s implements the proper welding equipment and best practices in an effort to obtain code-level welding quality at a cost-effective price to the customer.

Welding certifications and processes:

- AWS D1.1, AWS D1.2, API 1104 Latest Rev.

- GMAW, GMAW-P, GMAW-S

- GTAW

- MIG Aluminum Push-pull GMAW-P GMAW-S

Operational Aspect:

- Components and details for weldments are kitted with our barcoded job travelers

- Welders and Quality Manager discuss the job before fabrication is started.

Welding Equipment:

- Miller Invision MPa 450 (3)

- Miller Syncrowave 350 (2)

- Miller Dynasty 350 (2)

- Miller Deltaweld 450

- Miler Deltaweld 452

- Miller Deltaweld 651

- Miller Deltaweld 451

Tube Bending- We not only specialize in bending pipe for the Natural Gas Utility industry, but we also have extensive experience bending tubes for the defense industry. We are capable of working with a diverse set of materials and bending up to 3″ diameter tubes.

Tube End Forming- We offer reducing, expanding, notching, beading, flaring, and flanging. The Tube Diameter Max. Expansion / Reduction 3½″ x .120.

Miscellaneous Fabrications- Build-to-print small and large fabrications including but not limited to; platforms, ladders, staircases, towers, top kits, multilevel platforms, racks, material handling equipment, bases, caged ladders, and railings.

Kitting- Aaron’s Fabrication kitting programs produce significant operational savings. Buying kits reduce the cost associated with Receiving, inventory control, inspection, and purchasing just to name a few. Each BOM is procured, packaged, and delivered per your unique requirements. We feature complete barcoding capabilities to ensure maximum traceability and repeatability.

CAGE CODE: 75AZ8